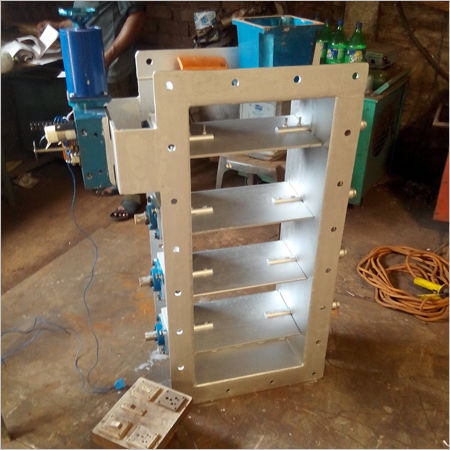

Automatic Louver Damper

Product Details:

Automatic Louver Damper Price And Quantity

- 2 Set

- 10000.00 - 50000.00 INR/Sheet

Automatic Louver Damper Trade Information

- West Bengal

- 10-15 Set Per Month

- 1 Months

- Standard Packaging

- West Bengal All India

- ISO 9001 : 2008

Product Description

Louvers Damper

On a gas conduit system, the assembly between flanges is handled by the Automatic Louver Damper. Louver dampers are made by using different opposed or parallel blades that allow ideal regulation, opening times and good closure. The standard model offered by VALVETEK is designed to operate at around 500 mbar pressures, and the recommended temperature is about 800ºC and speeds of below 30m/s. Closing degree range of 90%-99% of this relatively air tight valve can reach 100% on the introduction of an air sealing system. Designing of the standard Automatic Louver Damper model is done in a manner to maintain a horizontal position of the drive shafts. Although, option for vertical position assembly of the shafts is also possible as per demand.

Standard Louver DamperSeveral blades, rotating on the central shaft are fitted on the louver damper. Ends of these blades are joined to the conduits by the help of flanges. The louver damper is basically supplied as an individual part, leaving out the applications in which the unit dimensions need special transport.

Seating Options:Depending on the application, the louvers have two different types of seal design, the options are: swing-thru (closure from 90% to 97%) for surroundings with a density of dust (of below 1000 mg/Nm3); and the closure of 99% for step seat suitable for other applications needing top level of air insulation.

Bearing:Louvers supplied by VALVETEK have bearings located on the outside and detached from the packing. By following this way, they are kept safe from sources which can cause corrosion and heat, hence enhancing their operational life. This system also enables the packing change without any need to remove the bearing, which leads to easier future maintenance jobs.

Construction:Different material can be utilized in the fabrication of the body of the louver dampers. Size range for the standard construction includes 150x1500 mm (min) to 2000x2000 mm (max). Although, larger sizes can be constructed as per request. Reinforcing ribs are used for the construction of blades and are backed by two semi-shafts. Ideally rigid flat disc system withstands the operational pressures caused on these valves and does not cause major losses.

Insulation:VALVETEK offers its valves ready for 200 mm outer insulation. A space is provided for changing bearings and packings in the future without removing the insulation furnished.

Louver Damper with Sealing System Two parallel louvers are used in the making of louver damper with sealing system. In the space between the fitted louvers, the seal is created to inject ambient air comparatively more pressure than that of the gases flowing in the passages. A pressurized chamber is created by this system, which stops gases from leaking. This therefore ensures the air tightness of the valve with the passages. Design of this system is ideal for withstanding pressures below 250 mmwc. Electroventilator, a sealing valve, a sealing pipe and a dilation compensator are used in the making of the sealing system. Other features are just the same as the standard louver damper without sealing system.

Product Details

| Frequency | 50 HZ |

| Corrosion Resistance | yes |

| condition | new |

| Power Source | Electric |

| Max ambient temperature | 60 degree C |

| Material | MS |

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Call Me Free

Call Me Free