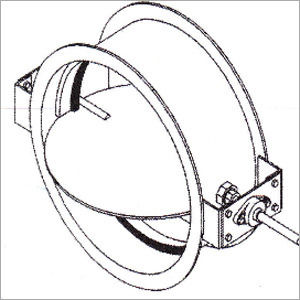

औद्योगिक स्लाइड गेट डैम्पर्स

उत्पाद विवरण:

औद्योगिक स्लाइड गेट डैम्पर्स मूल्य और मात्रा

- सेट/सेट्स

- सेट/सेट्स

- 10

औद्योगिक स्लाइड गेट डैम्पर्स व्यापार सूचना

- कोलकाता - पश्चिम बंगाल

- 10-15 प्रति महीने

- 1 महीने

- Yes

- हमारी नमूना नीति के बारे में जानकारी के लिए हमसे संपर्क करें

- स्टैंडर्ड पैकेजिंग

- पश्चिम बंगाल ऑल इंडिया

- आईएसओ 9001: 2008

उत्पाद वर्णन

Since the past 7 years, our organization has been renowned appreciation as the topmost manufacturer, exporter and supplier of Industrial Dampers like Electrically Operated Dampers, Square Louver Damper, Bypass Damper, High Temperature Damper and others. Extensively used in commercial and industrial sectors, the offered industrial dampers acts as a valve to regulate the air-flow within the installed spaces. The provided damper is manufactured by our adroit professionals using utmost quality components and contemporary techniques in line with international quality standards. Available in different designs and technical specifications, these Industrial Dampers is offered to the clients at reasonable prices.

Damper Performance

- Leaking Ratings : For the dampers, leakage increases significantly with blades number, than with the blades length.

- Torque Requirements : Closing Torque: The torque needed to power the blades together to sufficiently accomplish minimal possible leakage.

- Dynamic Torque: Need to overcome the high velocity airflow effect over the blades.

- Velocity Ratings : Higher velocity of industrial dampers in comparison to other shows that the former damper has stiffer blade. Also, linkage design that the bearings may be competent of higher loads.

- Temperature Ratings: Seals and Bearings are constructed of heat resistant material, if temperature rating is high.

- Pressure Ratings: When the blades are closed, maximal static pressure differential may be practical across the assembly.

- Ul Classification (fire/smoke) : UL 5555 (Regulation for Leakage Rated Dampers, for smoke control systems use)

Design Characteristics

Material Selection:

The material selection is characterized as per the operational conditions to which the industrial dampers will be exposed. This helps to ensure the best equipment performance. Gases from carbon combustion & fuel-oil, from cement factories, with sulphur, metal oxide, chloride etc. may reason early wear and troubles with corrosion, which should be analyzed in all cases.

Sealing Efficiency:

Closing degree of Industrial Damper is measured as an equivalent open area percentage. In other terms, an industrial damper with closing degree of 99% is equivalent to have 1% of the conduit area open. In reality, the flow leakage percentage is from 3 to 6 times said area, hence a damper with 99% closing degree will permit leakage of from 3% to 6% of the gas flow.

Damper

Industrial Damper can be regulation type or on/off type to which a position transmitter signal or positioner may be added for the purpose of automation.

Damper Types

Wheel & Gearbox: Manual system is appropriate for units that do not have a high automation level, and with small sized dampers.

Pneumatic: With 1⁄4 turn cylinder or linear; rendering very fast actuation. Involves a 5 to 7 bar air-pressure line. An air tank may be enclosed for emergency override.

Electric: Multi-turn electric motor or 1⁄4 turn electric motor, with gear box; supplied with a manual wheel for emergency override.

Technical Specifications:

| Operating temperature | 200ºC- 350ºC | 350ºC-550ºC | 550ºC-700ºC | 700ºC-800ºC | |||

| Body material | S-275JR | 15Mo3 | C13rMo44 | AISI 304 | AISI 316 | AISI 310 | AISI 321 |

| Disc Material | S-275JR | 15Mo3 | 13CrMo44 | AISI 304 | AISI 316 | AISI 310 | AISI 321 |

| Closure | S-275JR | AISI 304 | AISI 304 | AISI 304 | AISI 316 | AISI 310 | AISI 321 |

| Packing | Graphite | ||||||

| Shafts | AISI 420 | AISI 420 | AISI 304 | AISI 316 | AISI 310 | AISI 321 |

|

| Support | S-275JR (optional) | ||||||

| Insulation | Designed for 200 mm heat resistance | ||||||

Material Equivalences:

| EN 10027-2 | EN 10025 | DIN 17100 | ASTM |

| 1.0044 | S275JR | St 44-2 | A519 (1020) |

|

|

|

|

|

| EN 10027-2 | EN 10028-2 | DIN 17155 | ASTM |

| 1.5415 | 16Mo3 | 15Mo3 | A204GrB |

| 1.7335 | 13CrMo4-5 | 13CrMo44 | A387 (12) |

| EN 10027-2 | EN 10088-3 | AISI |

| 1.4021 | X20Cr13 | 420 |

| 1.4301 | X5CrNi18-10 | 304 |

| 1.4401 | X5CrNiMo17-2-2 | 316 |

| 1.4841 | X15CrNiSi25-21 | 310 |

| 1.4541 | X6CrNiTi18-10 | 321 |

Technical Specification of Industrial Dampers :

| Type of Damper | Electric on/off | Electric Regulation | Pneumatic on/off | Pneumatic Regulation |

| Voltage/A press | 380V/50 Hz2 | 380V/50 Hz2 | 6 bars | 6 bars |

| Accessories | ||||

| Limit Switches | Included | Included | Optional | Optional |

| Torque | Switches | Included | Included |

|

| Solenoid valves |

|

| Included | Included |

| 4-20 mA Positioners |

| Included | Included |

|

| 4-20 mA Position Transmitter | Optional | Optional |

| Optional |

| Air tank |

|

| Optional | Optional |

| Programmable Integrated Control | Optional | Optional |

|

|

| Emergency override | Wheel | Wheel | Optional | Optional |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

मुझे निःशुल्क कॉल करें

मुझे निःशुल्क कॉल करें